Structural Concrete Repairs

Concrete structures can develop a wide range of problems, caused by a variety of factors. Unlike wine,

concrete problems do not improve with age. The longer the problem is left, usually, the worst it becomes. A simple repair, in one area,

can often prevent the spread of deterioration to previously unaffected areas of the concrete.

Concrete structures can develop a wide range of problems, caused by a variety of factors. Unlike wine,

concrete problems do not improve with age. The longer the problem is left, usually, the worst it becomes. A simple repair, in one area,

can often prevent the spread of deterioration to previously unaffected areas of the concrete.

Some typical sources of problems found in concrete structures are as follows:

- Stresses generated within the structure itself.

- Environmental factors such as climate and pollution.

- Exposure to salts and chemicals.

- Corrosion of reinforcing steel.

- Service temperatures and the resulting thermal cycling.

- Failure or deterioration of other components of the structure.

Common problems that are found in concrete structures would be:

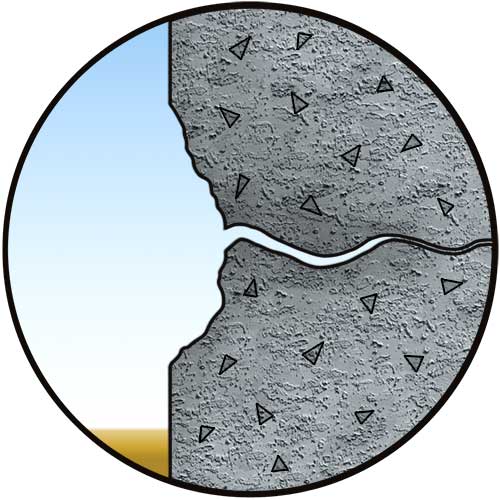

- Stress cracks.

- Shrinkage cracks.

- Surface spalls or delamination. These can range from very shallow spalls to several inches in depth.

- Exposed reinforcing steel.

- Galvanic corrosion of the reinforcing steel.

- Concrete that is spongy or saturated with contaminants.

- Severely weathered concrete.

- Rock pockets and/or honeycombed concrete.

- Sheared members such as columns and beams.

- Lifting and/or settlement of slabs, footers and foundations.

There are many repair materials on the market today and it is important to select the right product for the job. There are some jobs that will require a combination of different materials in order to execute the proper repair. A thorough understanding of the problem’s source, the repair materials to be used, installation techniques and job experience are vital to produce a long lasting repair.

Certain things to take into consideration, when faced with a concrete rehabilitation project, would be:

- Is the repair problem cosmetic or structural in nature?

- How extensive is the problem? This may require some non-destructive and/or destructive testing to evaluate the overall condition. In certain instances, the services of a structural engineer may need to be employed for safety concerns and specifying the repair design.

- How long should a particular type of repair last?

- Are the aesthetics of the repairs important? If the repairs are to be made to a finished surface, custom coloring or additional surface treatments may be required to “blend-in” the repair.

- Does the contractor have experience in performing these types of repairs? A client reference list is always a good idea.

- Will it be necessary to interrupt or shutdown access to the areas, while repairs are being made?

- Can the repairs be performed in phases, over an extended period of time, to accommodate budgetary restraints?

Some typical concrete repair techniques include the following:

- Hand Patching

- Form and Pour

- Epoxy Crack Injection

- Hydrophobic Grout Injection

- Spray-Applied Mortars

- Thin-set Resurfacing - Cementious and Epoxy Mortars

- Fluid-Applied Migrating Corrosion Inhibitors

- Cathodic Protection Systems

- Carbon Fiber Reinforcement

Compass Contracting has the resources and experience to help our clients design the best solution for their concrete restoration problems. We draw upon our experience and product knowledge, in conjunction with our manufacturers, to provide the most appropriate and cost effective repairs. If there is a need for structural engineering services, Compass Contracting has worked with many of the areas top engineering firms and can assist our clients with this as well.