Warehouse Slab Stabilization, Fredericksburg Distributing Company

This recently completed project involved stabilizing the floor slab sections along the control joints. The edges of the slab were experiencing vertical movement, or flexing, at the joints. It was determined that there were voids in the substrate, which extended approximately 24” on either side of the joints. The flexing was very noticeable each time forklifts ran over the joints.

The solution was to fill the underslab voids, to provide a solid bearing surface for the edges of the slabs. SikaGrout 212 was selected, as the material to fill these voids, because of its high flow characteristics and 2-stage shrinkage compensating mechanism.

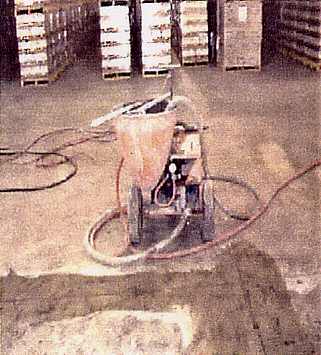

The first step was to drill a series of alternating, thru-slab holes, 18” on centers. This provided openings through which the grout could be placed into the voids. A peristaltic Carrousel Pump was used as the delivery mechanism for the grout.

The next step was to begin pumping the grout into the thru-slab holes, pumping into each hole until the grout was seen to emerge from the next hole, down the line. This procedure was repeated until all 2000 holes were addressed.

The final step of the repair was to seal the control joints. The existing joint filler was removed and the joint cavity cleaned. SikaFlex 2C self-leveling, 2-component, polyurethane sealant was selected to fill the joints.

The repair work was performed in sections to enable continuous warehouse operation.